Standard Cold Extrusion Coupler

Specifications

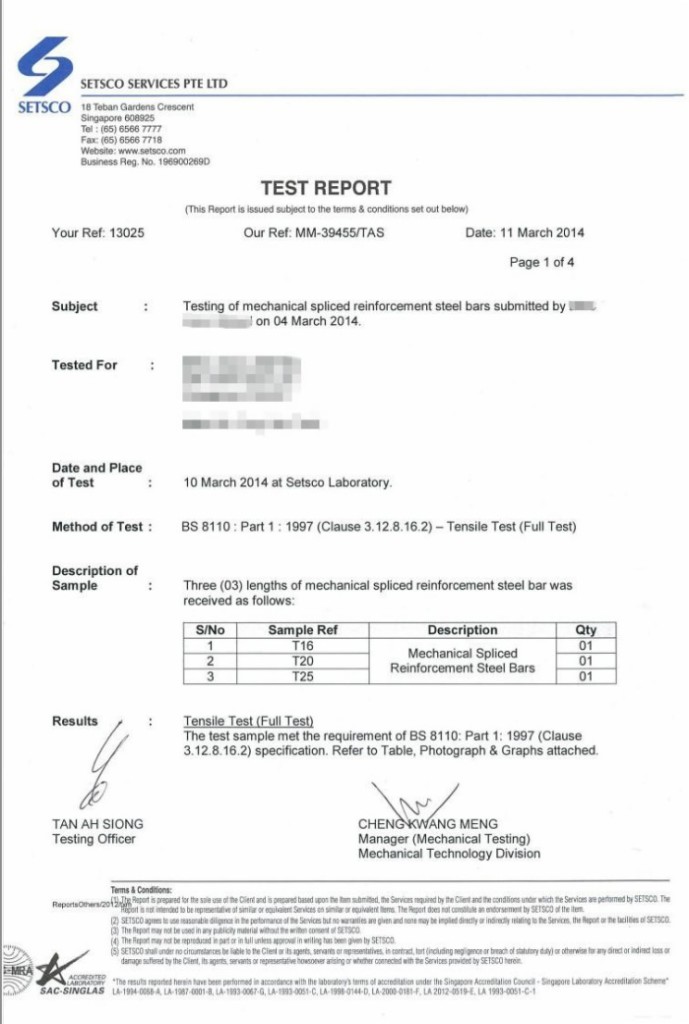

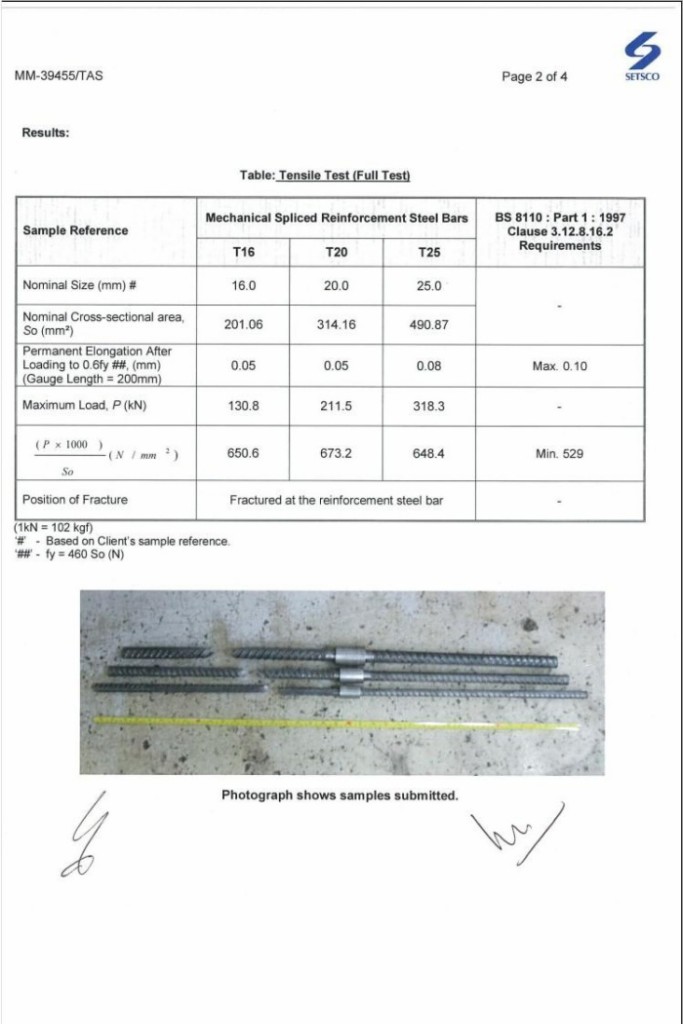

Aleono Cold Extrusion Rebar Coupler is the outright solution for connection with Ribbed Rebar. Made of high quality 20# carbon structural steel, the cold extrusion rebar coupler enjoys the high strength and it is able to connect reinforcing bars with the diameter of 16 to 40 mm. With no limitations on the type, composition, or weldability of steel bars, this rebar connector is widely used in bridge construction. It can meet with China standard of JGJ107-2010, UK standard of BS8110, USA standard of ACI318, VN standard of TCVN8163 and other international standards. Aleono Cold Extrusion Rebar Coupler including Standard Cold Extrusion Coupler, and Transition Cold Extrusion Coupler .

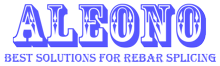

Standard Cold Extrusion Coupler is designed to splice two ribbed reinforcing bars with the same diameter. Firstly, the reinforcing bars to be connected are inserted into the cold extrusion coupler. Then, the coupler is squeezed by the clamp to deform plastically and connect tightly with the ribbed rebars.

Technical Parameters

|

Cold Extrusion Rebar Coupler |

|||||

|

Coupler Size |

Dia of Rebar |

Coupler dimensions (OD×WT×Length) |

Tolerances |

||

|

OD |

WT |

Length |

|||

|

T18 |

Ф18 |

33×5.0×110 |

±0.3 |

±0.5 |

±2 |

|

T20 |

Ф20 |

36×5.5×120 |

±0.3 |

±0.5 |

±2 |

|

T22 |

Ф22 |

40×6.0×132 |

±0.5 |

±0.6 |

±2 |

|

T25 |

Ф25 |

45×7.0×150 |

±0.5 |

±0.7 |

±2 |

|

T28 |

Ф28 |

50×8.0×168 |

±0.5 |

±0.8 |

±2 |

|

T32 |

Ф32 |

56×9.0×192 |

±0.5 |

±0.9 |

±2 |

|

T36 |

Ф36 |

63×10.0×216 |

±0.5 |

±0.10 |

±2 |

|

T40 |

Ф40 |

70×11.0×240 |

±0.5 |

±0.11 |

±2 |

Product Advantage

-

Cold Extrusion Rebar Coupler is constructed of high strength machinery steel grade is 20 carbon steel.

-

No special bar ends preparation needed.

-

Most commonly used for connection in columns, beams, piles etc where rebar length are insufficient.

-

Do not require the bars to be prepared, can be operated with light tools and require a minimal bar length.

-

Quick and convenient operation to shorten construction period and lower cost.

-

100% ultimate tensile and yield strength of rebar.

-

There is no open flame during the operation, which ensures high safety. The operation process is also eco-friendly, as there is no pollution caused.

-

No threading at ends and no reduction of the cross section Ares of the bar.

-

According to the inspection of National Construction Quality Supervision and Testing Center, the rebar coupler joint performance has reached the Grade I splicing rebar joint of JGJ107-2016 and JG/T 163-2013 Industry Standard.

Raw Material

20# Carbon Steel

|

Chemical Composition (%) |

C |

Si |

Mn |

S |

P |

Cr |

Ni |

Cu |

|

0.17~0.23 |

0.17~0.37 |

0.35~0.65 |

≤0.035 |

≤0.035 |

≤0.25 |

≤0.25 |

≤0.25 |

|

|

Mechanical Property |

Yield strength |

Tensile strength |

||||||

|

245 Mpa |

410 Mpa |

|||||||

Quality Control

Certificate

Packaging

PP Woven Bags are used inside, Wooden Case is used outside. Products also can be packed according to customer’s special demands.

Operation

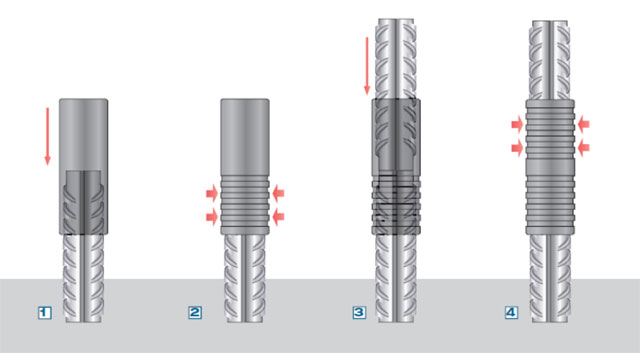

(1) Put the standard cold extrusion coupler onto the rebar end, ensure the length of this part is half of the coupler length.

(2) Press the coupler laterally with the Cold Extrusion Machine.

(3) Put the other side rebar end into the coupler.

(4) Press the coupler laterally with the Cold Extrusion Machine.

Application Jobsites

Application Projects