Nut Locking Rebar Coupler

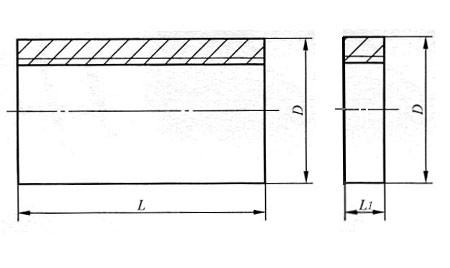

Specifications

Aleono Rolling Parallel Thread Rebar Coupler is designed to produce a full strength mechanical joint between reinforcing bars. It is used for rebar mechanical splicing in the concrete structure. It can connect re-bars of same or different diameters laterally, vertically and slantingly. It is broadly applied to the Tunnel, Tower, Bridge, Subway, Airport, Nuclear Power Station, High Rise Building and more. Aleono Parallel Thread Rebar Coupler including Standard Rebar Coupler, Position Rebar Coupler, Transition Coupler and more.

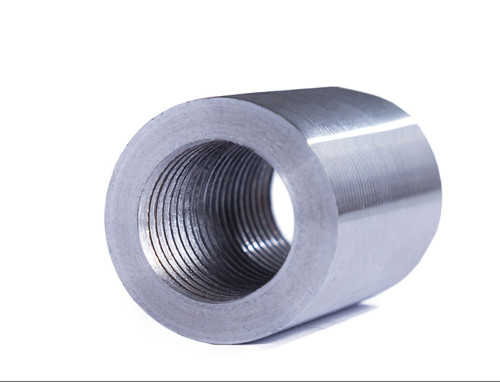

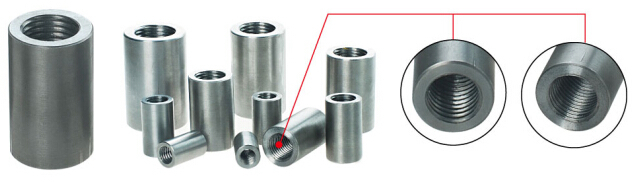

Nut Locking Rebar Coupler is designed to splice rebars which both sides completely cannot rotate. It consists of one standard rebar coupler and one lock nut or one flared rebar coupler with a lock nut. The main function of the nut is to meet the requirement of tightening torques and eliminate the residual deformation of the splice.

Nut Locking Rebar Coupler is designed to splice rebars which both sides completely cannot rotate. It consists of one standard rebar coupler and one lock nut or one flared rebar coupler with a lock nut. The main function of the nut is to meet the requirement of tightening torques and eliminate the residual deformation of the splice.

It is mostly adopted under L Bars and Prefabricated Bar Cages where the rotation of a bar is impossible.

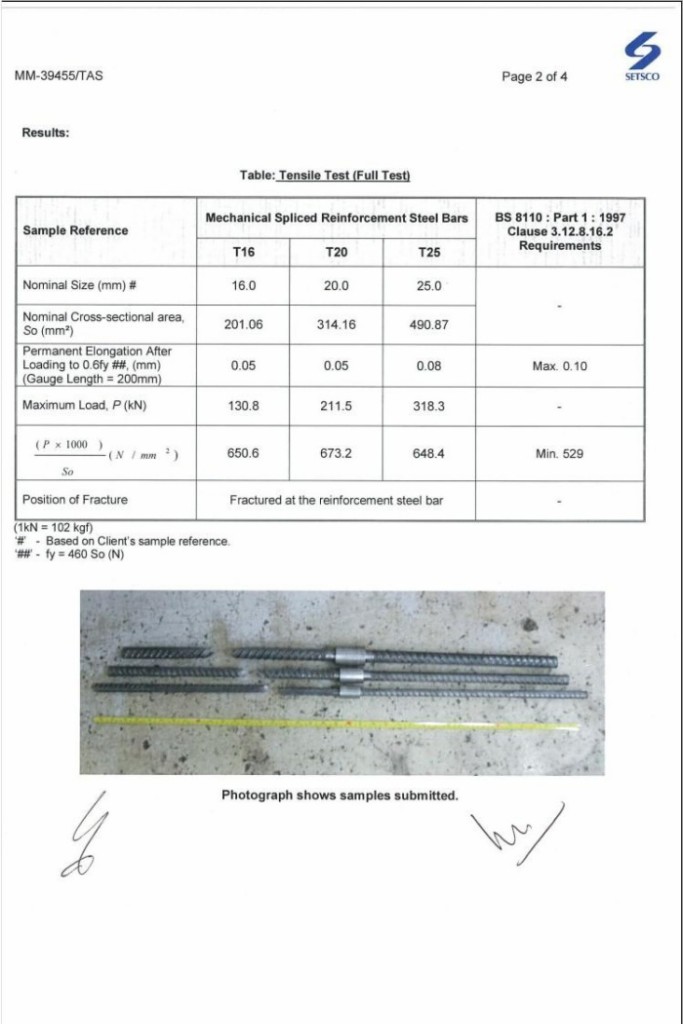

Technical Parameters

Product Advantage

-

Raw material-saving, high energy saving, high work efficiency.

-

Construction Environmental Protection. no flame, no noise pollution.

-

It is not be affected by the chemical compositions and types of reinforced bars and won’t be influenced by weather and work-site.

-

Low cost, simple operation.

-

Can be prefabricated and the construction period can be shortened.

-

High dimension precision, reliable quality and Stable performance.

-

High strength. The tensile strength usually more than 600 Mpa, it can reach 110% of yield strength of parent rebar.

-

After 2 million times of fatigue strength test, the connection is in good condition.

-

According to the inspection of National Construction Quality Supervision and Testing Center, the rebar coupler joint performance has reached the Grade I splicing rebar joint of JGJ107-2016 Industry Standard.

Raw Material

45# Carbon Steel

|

Chemical (%) |

C |

Si |

Mn |

Cr |

Ni |

Cu |

|

0.42-0.50 |

0.17-0.37 |

0.50-0.80 |

0.25 |

0.30 |

0.25 |

|

|

Mechanical |

Yield strength |

Tensile strength |

||||

|

355 Mpa |

600 Mpa |

|||||

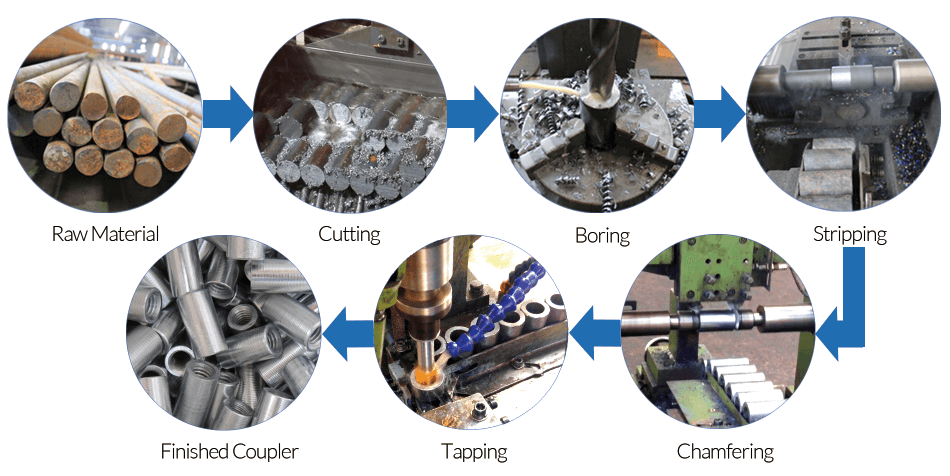

Production Processes

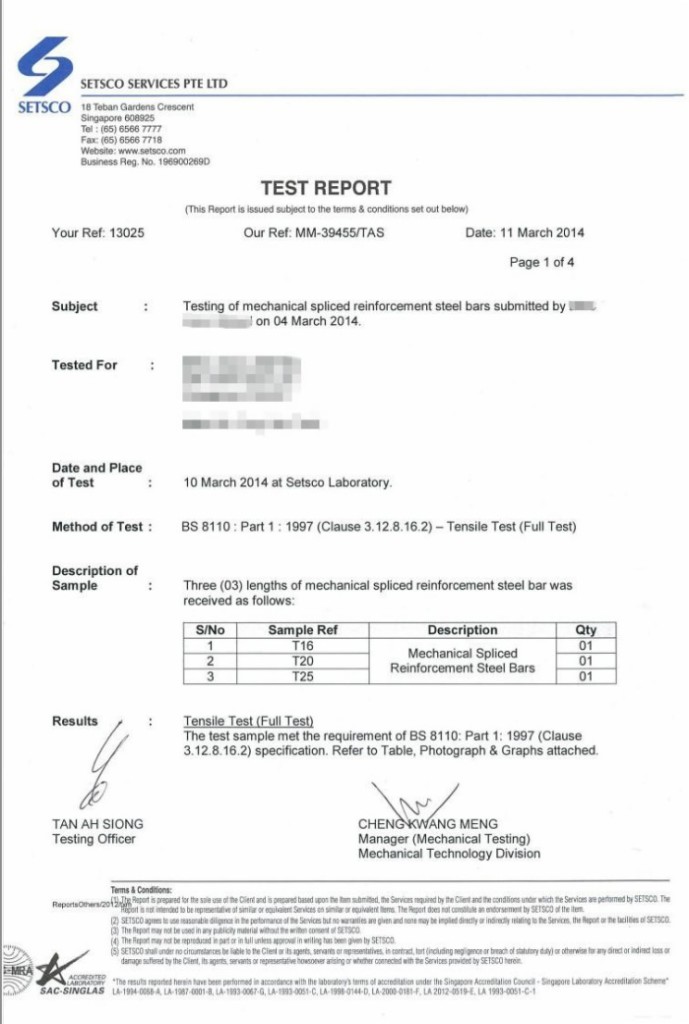

Quality Control

Certificate:

Packaging

PP Woven Bags are used inside, Wooden Case is used outside. Products also can be packed according to customer’s special demands.

Protection

To prevent dust and debris into the rebar coupler, we suggest you protect the coupler with Protective Cap before you use it.

Operation

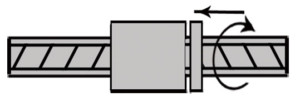

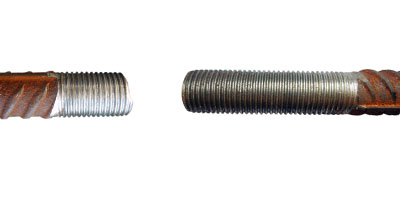

First, you should process thread on rebar end with the Rebar Threading Machine.

Ensure these two rebar threaded sectors with right-handed thread and the same diameter.

The length of the shorter rebar threaded sector is the half length of the coupler,

the length of the longer rebar threaded sector is the full coupler length plus the full nut length.

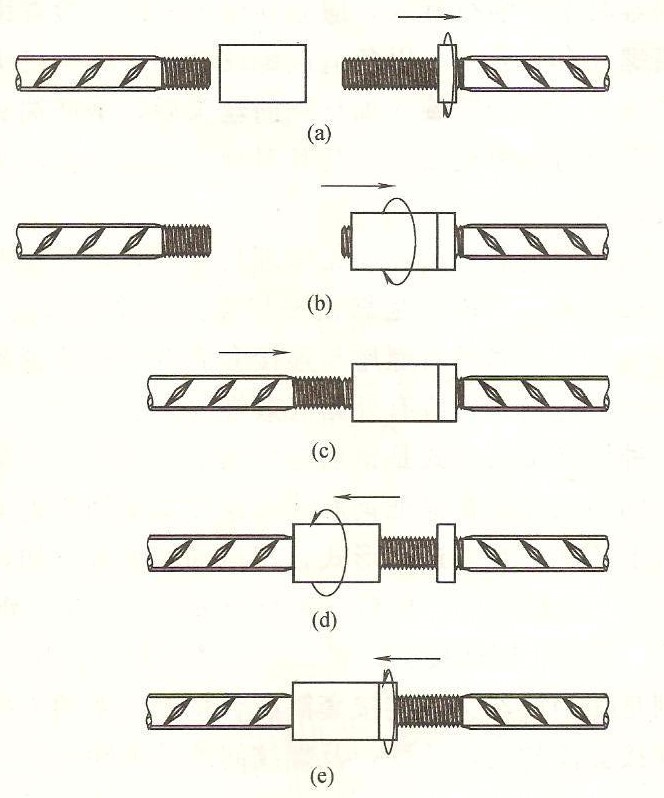

Then splice these two rebar threaded sectors.

(a) Rotate the lock nut onto the longer rebar threaded sector.

(b) Rotate the coupler onto the longer rebar threaded sector.

(c) Shift the shorter rebar threaded sector, ensure two rebar thread end can be touched each other.

(d) Rotate the coupler onto the shorter rebar threaded sector side.

(e) Rotate the lock nut to the behind the coupler, Fasten it with the torque spanner or working wrench.

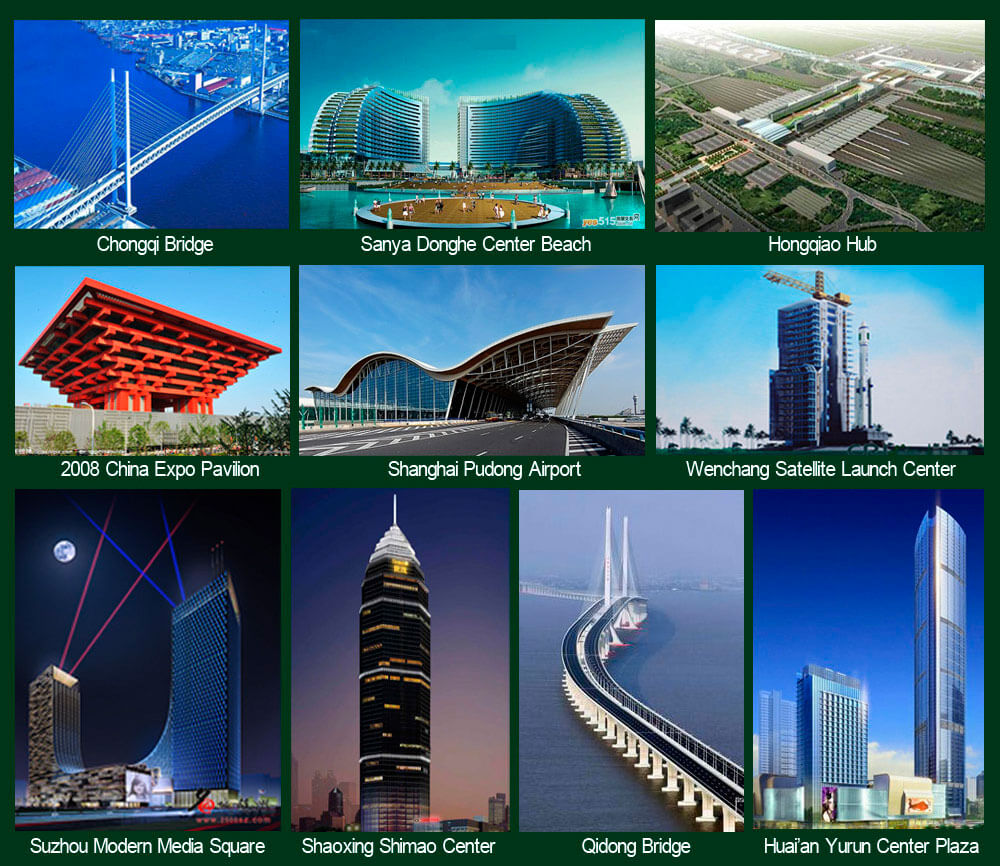

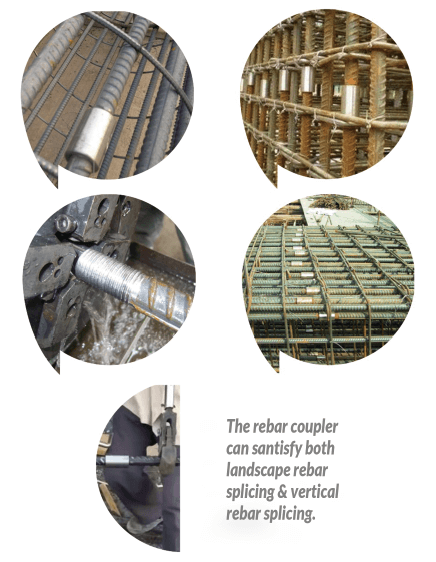

Application Jobsites

Application Projects